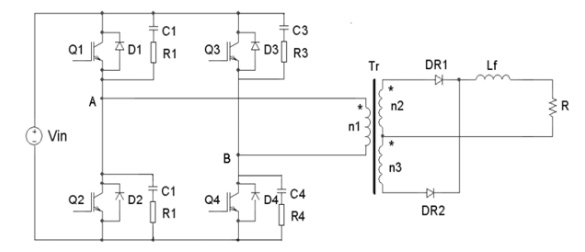

The welding machine is a special power supply, the output load is arc, and there is no-load and short-circuit process. The welding power supply must meet the requirements of the stability of the welding process. In many cases, the welding process is completed by people, and the power output often contacts people's body. Therefore, the welding power supply not only meets the requirements of the welding process, but also meets the personal safety requirements. The basic structure block diagram of the inverter welding machine is shown in the figure below, and the power supply of the power grid takes the domestic three-phase 380V as an example. After rectification, the input 380V three-phase AC becomes about 520v high-voltage DC, becomes high-frequency AC through inverter, and becomes smooth DC for welding after voltage reduction, rectification and filtering by transformer.

With the development of inverter circuit topology and the maturity of semiconductor devices, inverter welding machine appears. The circuit structure of inverter welding machine generally adopts the process of rectifier inverter re rectifier, that is, ac-dc-ac. Due to the increase of working frequency in the inverter process, the dynamic characteristics of the control process are improved, and the welder has small volume and light weight. IGBT power devices have the characteristics of FET voltage drive. The voltage level and current capacity are much larger than that of FET, so they are widely used in medium and high-power inverter welding machines. Their working frequency is more than 20kHz. The circuit form is mainly half bridge and full bridge, and the output capacity level of the welding machine can reach 2000a. Now IGBT inverter welding machines have become the mainstream, covering electrode arc welding Argon arc welding, CO2 gas shielded welding, consumable electrode argon arc welding, submerged arc welding, cutting machine and other arc welding power sources.

| Product Name | Bvces(V) | Package | Ic(A) | Vge(th)(V) | Vce(sat)(V) |

|---|---|---|---|---|---|

| SGT40T120FD3P7 | 1200 | TO-247-3L | 40 | 3.5~7.5 | <2.8 |

| SGT25T120FDM1P7 | 1200 | TO-247-3L | 25 | 3.5~7.5 | <2.6 |

| SGT60N60FD1P7 | 600 | TO-247-3L | 60 | 4.0~6.5 | <2.7 |

| SGT40N60FD1P7 | 600 | TO-247-3L | 40 | 4.0~6.5 | <2.7 |

Copyright ? 上海道徑電子科技有限公司 All Rights Reserved 滬ICP備05064014號-1 網站設計:JCE